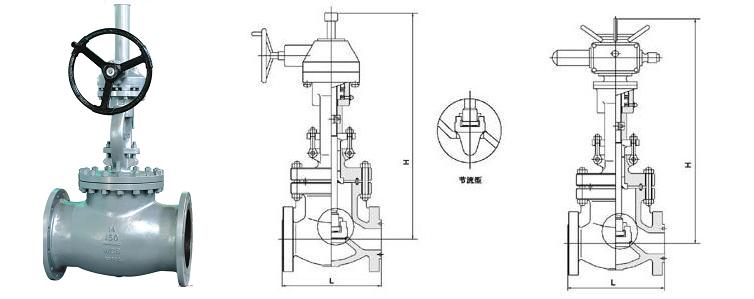

产品名称:伞齿轮铸钢直通式截止(节流)阀、伞齿轮直通式截止(节流)阀

产品型号:J541Y

产品介绍:J541H/Y伞齿轮铸钢直通式截止(节流)阀的启闭件是塞形的阀瓣,密封面呈平面或锥面 ,阀瓣沿流体的中心线作直线运动。阀杆的运动形式,有升降杆式(阀杆升降,手轮不升降),也有升降 旋转杆式(手轮与阀杆一起旋转升降,螺母设在阀体上)。

伞齿轮截止阀只适用于全开和全关,不允许作调节和节流。 伞齿轮截止阀属于强制密封式阀门,所以在阀门关闭时,必须向阀瓣施加压力,以强制密封面不 泄漏。当介质由阀瓣下方进入阀门时,操作力所需克服的阻力,是阀杆和填料的摩擦力与由介质的压力所产生的推力,关“伞齿轮截止阀” 的力比开“伞齿轮截止阀 ”的力大,所以阀杆的直径要大,否则会发生阀杆顶弯的故障。

伞齿轮铸钢直通式截止(节流)阀严格按BS 1873、API6D、 GB/T12235 标准设计制造,截止阀的阀瓣沿着中心定位作升降运动,(衬套采用耐磨性能好,摩擦系数小的特殊材料制作),动作灵活可靠,密封性能优良。产品广泛应用于石油、化工、制药、电力行业等各种工况的管路上。

|

公称压力

PN(Lb) |

强度试验

|

水密封试验

|

气密封试验

|

|||

|

MPa

|

Lbf/in2

|

MPa

|

Lbf/in2

|

MPa

|

Lbf/in2

|

|

|

150

|

3.1

|

450

|

2.2

|

315

|

0.5-0.7

|

60-100

|

|

300

|

7.8

|

1125

|

5.6

|

815

|

||

|

600

|

15.3

|

2225

|

11.2

|

1630

|

||

|

900

|

23.1

|

3350

|

16.8

|

2440

|

||

|

1500

|

38.4

|

5575

|

28.1

|

4080

|

||

|

2500

|

64.6

|

9367

|

47.4

|

6873

|

||

|

序号

NO. |

零件名称

Part Name |

碳钢系列

Carbon Steel |

不锈钢系列

Stainless Steel |

合金钢系列

Alloy steel |

低温钢系列

Low Temperature Steel |

|

1

|

阀体/Body

|

ASTM/A216 Gr WCB

|

ASTM/A351 Gr CF8

|

ASTM/217 Gr WC6

|

ASTM/A352 Gr LCB

|

|

2

|

阀瓣/Disc

|

ASTM/A105

|

ASTM/A182 F304

|

ASTM/182 F11

|

ASTM/A352 Gr LCB

|

|

3

|

阀座/ Seat Ring

|

ASTM/A105

|

ASTM/A182 Gr F304

|

ASTM/A182 Gr F304

|

ASTM/A182 Gr F304

|

|

4

|

阀杆/Stem

|

ASTM/ A182 F6a

|

ASTM/A182 Gr F304

|

ASTM/A182 Gr F304

|

ASTM/A182 Gr F304

|

|

5

|

密封垫片/Gasket

|

柔性石墨+SS304 / Soft Graphite+SS304

|

|||

|

6

|

阀盖/Bonnet

|

ASTM/A216 Gr WCB

|

ASTM/A351 Gr CF8

|

ASTM/217 Gr WC6

|

ASTM/A352 Gr LCB

|

|

7

|

双头螺柱/Stud

|

ASTM/A193 Gr B7

|

ASTM/A193 Gr B8

|

ASTM/A193 Gr B7

|

ASTM/A193 Gr B8

|

|

8

|

六角螺母/ Nut

|

ASTM/A194 Gr 2H

|

ASTM/A194 Gr 8

|

ASTM/A194 Gr 4

|

ASTM/A194 Gr 8

|

|

9

|

上密封座/Back Seat

|

ASTM/A182 Gr F6a

|

ASTM/A182 Gr F304

|

ASTM/A182 Gr F6a

|

ASTM/A182 Gr F6a

|

|

10

|

填料/Packing

|

柔性石墨 / Soft Graphite

|

柔性石墨/Soft Graphite(或PTFE)

|

柔性石墨 / Soft Graphite

|

|

|

11

|

销轴/Pin

|

ASTM/A276 TYPE 410

|

ASTM/A276 TYPE 304

|

ASTM/A276 TYPE 410

|

ASTM/A276 TYPE 304

|

|

12

|

活结螺栓/Eyebolt

|

ASTM/A193 Gr B7

|

ASTM/A193 Gr B8

|

ASTM/A193 Gr B7

|

ASTM/A193 Gr B7

|

|

13

|

螺母/Eyebolt Nut

|

ASTM/A194 Gr 2H

|

ASTM/A194 Gr 8

|

ASTM/A194 Gr 4

|

ASTM/A194 Gr 2H

|

|

14

|

填料压套/Packing Bushing

|

ASTM/A182 Gr F6a

|

ASTM/A182 Gr F304

|

ASTM/A182 Gr F6a

|

ASTM/A182 Gr F304

|

|

15

|

填料压板/Gland

|

ASTM/A216 Gr WCB

|

ASTM/A351 Gr CF8

|

ASTM/217 Gr WC6

|

ASTM/A352 Gr LCB

|

|

16

|

阀杆螺母/Stem Nut

|

ASTM/A439GR.D2(或ZCuAL10Fe3)

|

|||

|

17

|

轴承压盖/Stem Nut Retainer

|

ASTM/A108 Gr1020

|

ASTM/A182 Gr F304

|

ASTM/A108 Gr1020

|

ASTM/A182 Gr F304

|

|

18

|

油杯/Grease Cup

|

铜合金 / Copper Alloy

|

|||

|

19

|

手轮/Handwheel

|

ASTM/A536 60-40-18

|

|||

|

20

|

手轮螺母/ Handwheel Nut

|

Carbon Steel or Alloy Steel

|

|||

|

|

适用介质

|

水、蒸汽、油品等

|

硝酸、醋酸等

|

水、蒸汽、油品等

|

水、蒸汽、油品等

|

|

|

适用温度

|

—29℃~425℃

|

—29℃~200℃

|

—29℃~550℃

|

—46℃~345℃

|

|

Class 150 / 10K

|

|||||||||||||

|

DN

|

mm

|

50

|

65

|

80

|

100

|

125

|

150

|

200

|

250

|

300

|

350

|

400

|

450

|

|

NPS

|

in

|

2

|

2-1/2

|

3

|

4

|

5

|

6

|

8

|

10

|

12

|

14

|

16

|

18

|

|

L(RF-BW)

|

mm

|

203

|

216

|

241

|

292

|

356

|

406

|

495

|

622

|

698

|

787

|

914

|

978

|

|

in

|

8.0

|

8.5

|

9.5

|

11.5

|

14

|

16.0

|

19.5

|

24.5

|

27.5

|

31.0

|

36.0

|

38.5

|

|

|

L(RTJ)

|

mm

|

216

|

229

|

254

|

305

|

369

|

419

|

508

|

635

|

711

|

800

|

927

|

991

|

|

in

|

8.5

|

9

|

10

|

12

|

14.5

|

16.5

|

20

|

25

|

28

|

31.5

|

36.5

|

39

|

|

|

H

|

mm

|

380

|

376

|

433

|

495

|

560

|

574

|

710

|

797

|

995

|

1387

|

1356

|

1980

|

|

in

|

15

|

14.8

|

17.0

|

19.5

|

22

|

22.6

|

28

|

31.4

|

39.17

|

54.6

|

53.4

|

78

|

|

|

Do

|

mm

|

200

|

250

|

250

|

250

|

300

|

350

|

400

|

500

|

560

|

560

|

600

|

680

|

|

in

|

8

|

10

|

10

|

10

|

12

|

14

|

16

|

20

|

22

|

22

|

24

|

27

|

|

|

RF

|

Kg

|

20

|

26

|

35

|

65

|

90

|

105

|

182

|

295

|

410

|

685

|

900

|

1800

|

|

BW

|

Kg

|

18

|

23

|

28

|

55

|

75

|

85

|

150

|

225

|

330

|

595

|

800

|

1650

|

|

Class 300 / 20K

|

||||||||||||

|

DN

|

mm

|

50

|

65

|

80

|

100

|

125

|

150

|

200

|

250

|

300

|

350

|

400

|

|

NPS

|

in

|

2

|

2-1/2

|

3

|

4

|

5

|

6

|

8

|

10

|

12

|

14

|

16

|

|

L(RF-BW)

|

mm

|

267

|

292

|

318

|

356

|

400

|

444

|

559

|

622

|

711

|

838

|

864

|

|

in

|

10.5

|

11.5

|

12.5

|

14

|

15.8

|

17.5

|

22

|

24.5

|

28.0

|

39.0

|

42.0

|

|

|

L(RTJ)

|

mm

|

283

|

308

|

334

|

372

|

416

|

461

|

575

|

638

|

727

|

854

|

880

|

|

in

|

11.1

|

12.1

|

13.1

|

14.6

|

16.4

|

18.1

|

22.6

|

25.1

|

28.62

|

33.62

|

34.64

|

|

|

H

|

mm

|

396

|

415

|

462

|

550

|

695

|

741

|

800

|

1132

|

1172

|

1435

|

1650

|

|

in

|

15.6

|

16.3

|

18.2

|

21.7

|

27.7

|

29.2

|

31.5

|

446

|

46.1

|

56.5

|

65

|

|

|

Do

|

mm

|

200

|

250

|

250

|

300

|

350

|

400

|

500

|

500

|

600

|

680

|

800

|

|

in

|

8

|

10

|

10

|

12

|

14

|

16

|

20

|

20

|

24

|

27

|

31.5

|

|

|

RF

|

Kg

|

30

|

38

|

60

|

90

|

130

|

178

|

280

|

380

|

580

|

780

|

1100

|

|

BW

|

Kg

|

25

|

30

|

52

|

75

|

110

|

150

|

220

|

305

|

530

|

660

|

960

|

|

Class 600

|

|||||||||||

|

DN

|

mm

|

50

|

65

|

80

|

100

|

150

|

200

|

250

|

300

|

350

|

400

|

|

NPS

|

in

|

2

|

2-1/2

|

3

|

4

|

6

|

8

|

10

|

12

|

14

|

16

|

|

L(RF-BW)

|

mm

|

292

|

330

|

356

|

432

|

559

|

660

|

787

|

838

|

889

|

991

|

|

in

|

11.5

|

13.0

|

14.0

|

17.0

|

22.0

|

26.0

|

31.0

|

33.0

|

35.0

|

39.0

|

|

|

L(RTJ)

|

mm

|

295

|

333

|

359

|

435

|

562

|

664

|

792

|

841

|

892

|

994

|

|

in

|

11.62

|

13.12

|

14.12

|

17.12

|

22.12

|

26.12

|

31.12

|

33.12

|

35.12

|

39.12

|

|

|

H

|

mm

|

406

|

505

|

585

|

675

|

760

|

1080

|

1280

|

1495

|

1800

|

1930

|

|

in

|

16

|

19.9

|

23

|

26.5

|

29.9

|

42.5

|

50.4

|

58.8

|

70.9

|

76.0

|

|

|

Do

|

mm

|

250

|

250

|

300

|

350

|

450

|

600

|

680

|

800

|

800

|

850

|

|

in

|

10

|

10

|

12

|

14

|

18

|

24

|

27

|

31.5

|

31.5

|

33.5

|

|

|

RF

|

Kg

|

39

|

59

|

70

|

125

|

260

|

470

|

810

|

1080

|

1350

|

1660

|

|

BW

|

Kg

|

35

|

52

|

60

|

98

|

210

|

390

|

680

|

950

|

-

|

-

|

|

Class 900

|

|||||||||||

|

DN

|

mm

|

50

|

65

|

80

|

100

|

150

|

200

|

250

|

300

|

350

|

400

|

|

NPS

|

in

|

2

|

2-1/2

|

3

|

4

|

6

|

8

|

10

|

12

|

14

|

16

|

|

L(RF-BW)

|

mm

|

368

|

419

|

381

|

457

|

610

|

737

|

838

|

965

|

1029

|

1130

|

|

in

|

14.5

|

16.5

|

15.0

|

18.0

|

24.0

|

29.0

|

33.0

|

38.0

|

40.5

|

44.5

|

|

|

L(RTJ)

|

mm

|

371

|

422

|

384

|

460

|

613

|

740

|

841

|

968

|

1038

|

1140

|

|

in

|

14.62

|

16.62

|

15.12

|

18.12

|

24.12

|

29.12

|

33.12

|

38.12

|

40.88

|

44.88

|

|

|

H

|

mm

|

695

|

695

|

77.5

|

855

|

1065

|

1320

|

1540

|

1840

|

2135

|

2380

|

|

in

|

27.4

|

27.3

|

30.5

|

33.7

|

42

|

52

|

60.6

|

72.5

|

84.1

|

93.8

|

|

|

Do

|

mm

|

300

|

400

|

400

|

400

|

500

|

600

|

750

|

850

|

850

|

900

|

|

in

|

12

|

16

|

16

|

16

|

20

|

24

|

30

|

34

|

34

|

36

|

|

|

RF

|

Kg

|

80

|

115

|

105

|

190

|

395

|

680

|

960

|

1680

|

2180

|

3400

|

|

BW

|

Kg

|

70

|

105

|

89

|

155

|

350

|

610

|

800

|

1410

|

1850

|

3080

|

|

Class 1500

|

|||||||||

|

DN

|

mm

|

50

|

65

|

80

|

100

|

150

|

200

|

250

|

300

|

|

NPS

|

in

|

2

|

2-1/2

|

3

|

4

|

6

|

8

|

10

|

12

|

|

L(RF-BW)

|

mm

|

368

|

419

|

470

|

546

|

705

|

832

|

991

|

1130

|

|

in

|

14.5

|

16.5

|

18.5

|

21.5

|

27.75

|

32.75

|

39

|

44.5

|

|

|

L(RTJ)

|

mm

|

371

|

422

|

473

|

549

|

711

|

841

|

1000

|

1146

|

|

in

|

14.62

|

16.62

|

18.62

|

21.62

|

28., 0

|

33.13

|

39.38

|

45.12

|

|

|

H

|

mm

|

695

|

695

|

770

|

875

|

1095

|

1400

|

1600

|

1905

|

|

in

|

27.4

|

27.3

|

30.3

|

34.45

|

43.1

|

55.1

|

63

|

75

|

|

|

Do

|

mm

|

300

|

400

|

500

|

500

|

600

|

750

|

850

|

960

|

|

in

|

12

|

16

|

20

|

20

|

24

|

30

|

34

|

38

|

|

|

RF

|

Kg

|

80

|

115

|

180

|

235

|

520

|

1150

|

1950

|

|

|

BW

|

Kg

|

70

|

105

|

140

|

200

|

460

|

1000

|

1700

|

|

|

Class 2500 (中部为自紧密封)

|

|||||||||

|

DN

|

mm

|

50

|

65

|

80

|

100

|

150

|

200

|

250

|

300

|

|

NPS

|

in

|

2

|

2-1/2

|

3

|

4

|

6

|

8

|

10

|

12

|

|

L(RF-BW)

|

mm

|

451

|

508

|

578

|

673

|

914

|

1022

|

1270

|

1422

|

|

in

|

17.75

|

20.0

|

22.75

|

26.5

|

36.0

|

40.25

|

50.0

|

56.0

|

|

|

L(RTJ)

|

mm

|

454

|

514

|

584

|

683

|

927

|

10.38

|

1292

|

1445

|

|

in

|

17.87

|

20.25

|

23.0

|

26.88

|

36.5

|

40.87

|

50.88

|

56.88

|

|

|

H

|

mm

|

498

|

525

|

622

|

698

|

985

|

1220

|

1425

|

1540

|

|

in

|

19.6

|

20.7

|

24.5

|

27.5

|

38.8

|

48

|

56.1

|

60.6

|

|

|

Do

|

mm

|

400

|

500

|

500

|

600

|

700

|

900

|

1050

|

1050

|

|

in

|

16

|

20

|

20

|

24

|

24.0

|

36

|

42

|

42

|

|

|

RF

|

Kg

|

120

|

155

|

200

|

280

|

780

|

1350

|

2300

|

3250

|

|

BW

|

Kg

|

110 | 135 | 175 | 245 | 690 | 1200 | ||

订货须知:

一、①伞齿轮直通式截止(节流)阀产品名称与型号②伞齿轮直通式截止(节流)阀口径③伞齿轮直通式截止(节流)阀是否带附件以便我们的为您正确选型。

二、若已经由设计单位选定凯斯特公司的伞齿轮直通式截止(节流)阀型号,请按伞齿轮直通式截止(节流)阀型号直接向我司销售部订购。

三、当使用的场合非常重要或环境比较复杂时,请您尽量提供设计图纸和详细参数,由我们的凯斯特阀门专家为您审核把关。

感谢您访问我们的网站【http://www.hbkst.cn】,如有任何疑问.您可以致电给我们,我们一定会尽心尽力为您提供优质的服务。